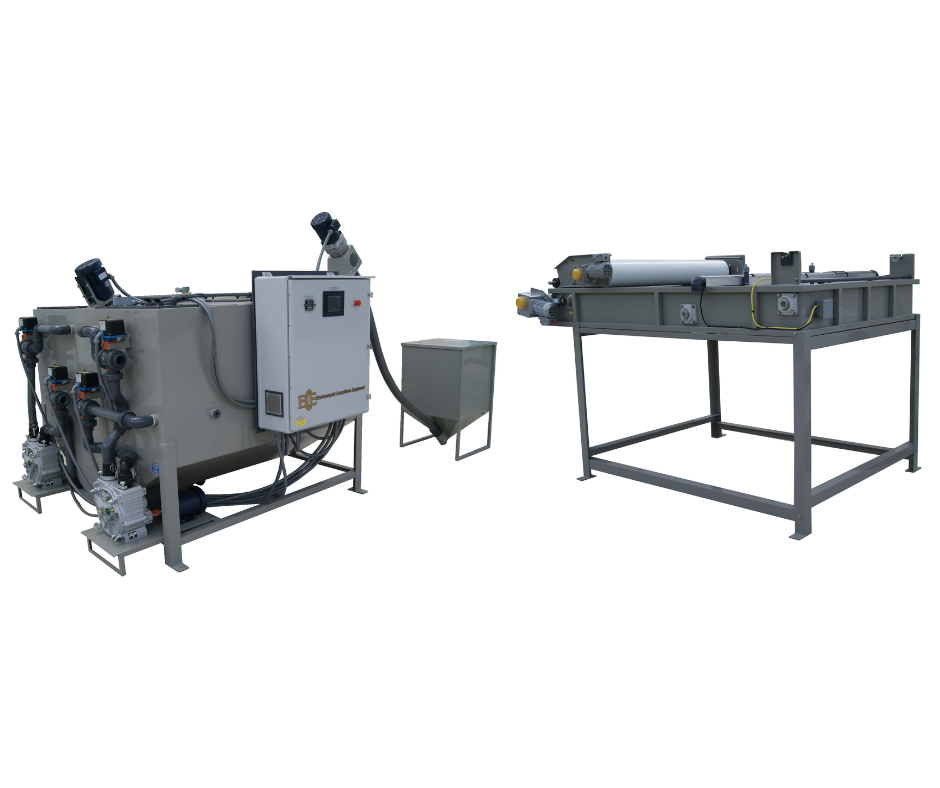

The ClearFlow Automatic ClearFloc Wastewater Treatment Systems represent the latest advancements in water treatment technology.

These units are fully automated continuous batch treatment systems; meaning that they will treat a volume of water and then treat additional volumes one after another until the entire volume is treated.

The systems utilize several unique cost-saving technologies which are energy efficient and help protect the environment.

Fully automated wastewater treatment process utilizing a bentonite based and polymer flocculent, ClearFloc, to remove solids, oils, inks, paint, dyes, metals, BOD and COD.

Consider the Benefits of a ClearFlow System

- ClearFlow Systems provide consistent treatment in a fully automated and completely adaptable format. All controls and motor functions have variability to the infinite level to allow the process to be “tuned” to your specific needs. The systems include Ethernet capability to allow access to critical information and to provide email notification of operational status.

- ClearFlow Systems are constructed of 304 Stainless Steel and designed to be rugged and long lasting. The system is also powder coated and then a ceramic clear coat is applied in entirety. All components have a high level of compatibility with the potential variety of waste streams it may encounter. Components selected are well known for quality and long lasting service.

- ClearFlow Systems can be warranted for Five Years on replacement parts. Every component for 1,825 days.

- ECE’s blend’s of Clear Floc Encapsulate provides assurance in the proper treatment of the waste stream generating a high quality effluent while ensuring the resulting spent Clear Floc will pass TCLP and be able to be discharged as a non hazardous waste. ECE will provide assurance in the form of a warranty that a TCLP will be passed.

- ClearFlow Systems not only provide a quality effluent but also reduced cost of operation compared to similar operations. ECE can provide a cost of operation warranty that assures the client the Environmental Compliance Equipment cost to operate will not exceed a preset cost. Now our clients can write a number on the P&L for waste treatment cost and know it will not exceed that line item.

- ClearFlow Systems can be applied to a variety of waste streams and can be programmed to process multiple waste streams using a single system. Multiple waste streams that cannot be comingled can be treated using one ClearFlow system. Adaptability of the programming allows one system to treat multiple wastes.

- ClearFlow Systems can provide water for reuse in all applications using post treatment technologies to provide high quality recycled water. We use corona discharge ozone, UV ozone and UV sterilization. Various media’s form carbon, multimedia, ion exchange and filtration.

Wastewater Case Studies

Waste Collection Maintenance Facility

The Problem: A waste hauling company takes pride in ensuring the collection trucks are clean and presentable to their clients, you, and I. Each day, every truck is washed to remove the day’s accumulation of road film, oil, and grease, some fluids from the collection, and landfill solids. The company

Tortilla Manufacturer

The Problem: Tortilla manufacturer generates wastewater in the process of cleaning the tortilla and tortilla chip manufacturing machines. Cleanings are constant throughout the week and on the weekend the entire plant is cleaned and sanitized. These cleaning evolutions generate a volume of wastewater that is loaded with FOG ( Fats,

Tank Wash Facility LA.

The Problem: A company washes tank trailers and ISO tank containers. The variety of wastes encountered presents a challenge in the treatment of the generated waste. They required that the water be recycled at a rate of at least 50%. The CF 400 was selected as the primary treatment with

A Drilling Pipe Machine Works Facility

The Problem: A Pipe Machining company manufactures a drilling pipe at its TX facility. Manufacturing consists of taking raw pipe and milling threads and/or attaching couplings to the ends of the pipe of various diameters. In this process, two main waste streams are generated. First is a coolant waste generated

Oil Exploratory Company, WA Australia

The Problem: This oil exploratory company generates wastewater in the process of cleaning oilfield tools used on offshore oil rigs. The tools are loaded with oil, solids, salts, and a variety of chemicals and metals. The tools are washed using a pressure washer then the water is collected and sent

Australian Cardboard Manufacturer

The Problem: In the manufacturing of cardboard boxes, ink is used to print a client’s information on the container. During the change-outs of the printing press, the ink is washed off the printing roller to ready the process for the next client’s container. This washing generates a waste ink high

An Aerospace Fasteners Manufacturing Facility

The Problem: The company manufactures various types of fasteners for the aerospace industry. In the process of manufacturing, several waste streams are generated that contain oil, various metals, and solids. In order to save operating costs in the form of hauling charges, The company needed a way to treat the

Electrical Components Manufacturing, FL

The Problem: A well known electrical components company manufactures electrical wiring components such as grounding rod clamps, wiring crimps, end connectors, distribution components, and a variety of other electrical parts. In this process, they generate a waste stream containing various metals including copper, zinc, and aluminum. The CF 200 system

County Transit Bus Maintenance Facilities

The Problem: A County Transit operates three bus maintenance facilities. Each facility generates wash wastewater in the process of cleaning buses. Engine degreasing, undercarriage wash, wheel cleaning, and general maintenance washing generate wastewater contaminated with oils, grease, and metals including Zinc and Lead. They needed a system that could remove

County Bus Maintenance Facility

The Problem: Undercarriage wash operations generate a waste stream of emulsified oils, metals, and organics. High emulsifying degreaser provides easy removal of oils and grease from the vehicle using a pressure washer but leaves wastewater that is difficult to treat for either recycle or discharge. Oils and grease remain in

The Clearflow Process

We have performed initial treatment on the sample to determine feasibility using the ClearFlow process scenario. The results we have obtained are very good considering the clarity of the post treated sample. The photo below provides a visual representation of the ClearFlow process scenario. A more detailed testing is being

ISO Container Wash

We have performed initial treatment on the sample to determine feasibility using the ClearFlow process scenario. The results we have obtained are very good considering the clarity of the post-treated sample. The photo below provides a visual representation of the ClearFlow process scenario. A more detailed testing is being completed

Transport Company

The Problem: This company is a hazardous materials transport company based in Illinois with 25 locations around the Eastern US. In several locations they operate wash racks to keep the fleet of trucks clean. They generate a volume of waste water that is contaminated with oils, solids, organics and salts.